How Test Chambers Shape Modern Product Reliability

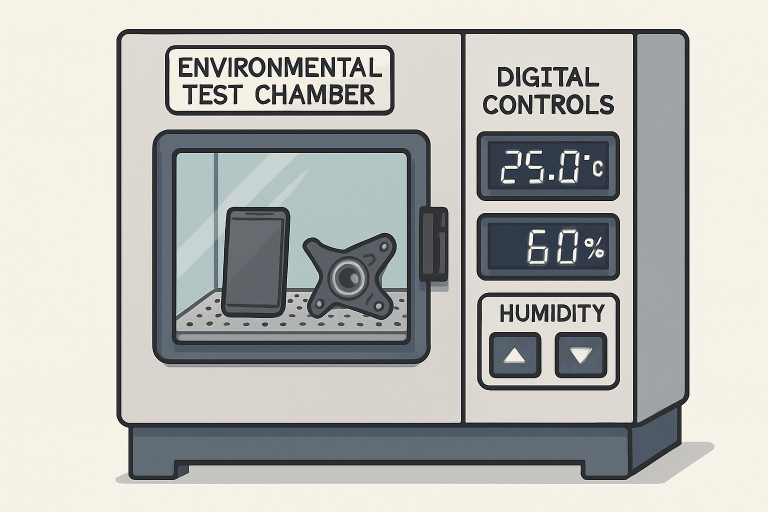

In today’s high-stakes manufacturing landscape, ensuring product reliability isn’t just a matter of reputation—it’s essential for safety, compliance, and customer satisfaction. Test chambers are pivotal in this process, providing manufacturers with the controlled settings needed to evaluate how products perform under stress. Whether measuring a smartphone’s tolerance to high heat or assessing an automotive component’s durability in freezing temperatures, environmental test chamber service ensures accurate, repeatable testing throughout a product’s lifecycle.

These chambers replicate a wide array of environmental conditions, helping companies uncover vulnerabilities before products ever reach consumers. By proactively testing during development and before market release, brands can reduce recalls, minimize warranty claims, and enhance trust. Test chambers have rapidly evolved into cornerstones of reliability engineering across industries, driven by ever-higher standards and increasingly stringent regulatory frameworks.

As expectations rise and products become more complex, the ability to validate performance in simulated real-world environments becomes a competitive advantage. Modern test chambers, when paired with skilled technical teams and integrated services, form an essential defense against costly field failures and negative press.

By understanding the diverse types and functions of test chambers, businesses can optimize investments in reliability, safety, and quality. This comprehensive overview explores how test chambers empower innovation and consumer confidence across industries.

Table of Contents

Importance of Test Chambers

Test chambers enable precise replication of environmental conditions, such as temperature variations, humidity, altitude, and vibration—critical for identifying product weaknesses. Through rigorous, repeatable testing, engineers can identify and address design flaws that may otherwise manifest as hazardous or costly field failures.

Manufacturers across sectors such as electronics, automotive, aerospace, and pharmaceuticals rely on these chambers to verify compliance, validate safety claims, and shorten time-to-market. By mitigating risks early, businesses can avoid expensive recalls, regulatory setbacks, and damage to their brand reputation. Rigorous environmental testing is not just best practice—it’s fast becoming an industry mandate.

Types of Test Chambers

Multiple types of test chambers serve varying purposes, each designed to simulate specific stressors:

- Temperature and Humidity Chambers: Used to assess durability under fluctuating or extreme temperature and humidity conditions, crucial for electronics and industrial hardware.

- Vibration Test Chambers: Evaluate performance against mechanical stresses encountered during transportation, operation, and accidental drops.

- Thermal Shock Chambers: Subject products to rapid, extreme temperature changes for accelerated lifecycle testing, commonly used for materials, components, and circuit boards.

- Altitude Chambers: Replicate high-altitude, low-pressure conditions necessary for aerospace and defense components.

Some facilities opt for multi-purpose chambers that can combine sets of conditions, streamlining the testing of increasingly sophisticated products. There’s a growing trend in modular chamber design, enhancing adaptability for future product requirements.

Applications Across Industries

The transformative value of test chambers is seen across a variety of sectors:

- Electronics: Devices like smartphones, wearables, and servers must be reliable across diverse global climates and usage scenarios.

- Automotive: Parts and assemblies—ranging from batteries in electric vehicles to brake systems—are validated for performance over millions of simulated road miles and a broad spectrum of environments.

- Pharmaceuticals: Medicines undergo stability and shelf-life studies to guarantee efficacy throughout global supply chains.

- Aerospace: Materials and avionics are tested for robustness against altitudinal flux, vibration, and temperature extremes, all of which can affect flight safety.

Technological Advancements

The past decade has seen remarkable advancements in test chamber technologies. The fusion of IoT-enabled sensors and cloud-based controls now enables real-time remote monitoring, instant alerts, and dynamic test data analytics. These features reduce manual oversight, speed up troubleshooting, and ensure testing consistency regardless of location.

Moreover, smart chambers can simulate overlapping environmental stressors, allowing for multi-axis testing that reflects real-world unpredictability. As automation and AI integrate further, expect chambers to self-diagnose issues, optimize performance schedules, and provide predictive maintenance suggestions—driving efficiency and accuracy even higher.

Challenges in Test Chamber Utilization

Despite their strengths, several hurdles can undermine the full potential of test chambers:

- Skilled Workforce Shortage: Training for increasingly sophisticated systems is intensive, and there is a notable shortage of qualified technicians.

- Maintenance Complexity: Precise calibration and ongoing maintenance are critical for accuracy; neglect can lead to data errors or equipment downtime.

- Standardization Issues: While some universal guidelines exist, industries still grapple with inconsistent protocols, which can affect the comparability of test results.

Navigating these challenges requires investments not only in state-of-the-art chambers but also in ongoing education and rigorous internal quality control.

Best Practices for Effective Testing

Maximizing the benefits of environmental chamber testing is possible by adhering to industry best practices:

- Regular Calibration: Schedule periodic calibration of test chambers to ensure measurements remain precise and credible.

- Comprehensive Training: Develop robust technician training programs that cover both chamber operation and data interpretation.

- Adherence to Standards: Strictly follow guidelines from leading bodies, such as ASTM and ISO, to ensure validity and intra-industry comparability.

Continuous improvement, embracing new technology, and regularly evaluating testing processes drive both product innovation and customer trust.

Conclusion

Environmental test chambers play an indispensable role in product reliability and innovation. As simulation technology advances and industries face mounting pressure to improve quality, safety, and speed, the value of rigorous, reliable testing grows. By prioritizing proper maintenance, skilled operation, and adherence to best practices, manufacturers can confidently launch products that excel under any condition—creating lasting advantages in today’s dynamic marketplace. As global standards continue to evolve, environmental testing ensures products remain compliant while meeting customer expectations for performance and durability. Investing in advanced test chamber capabilities not only reduces costly failures but also strengthens brand credibility and long-term market success.