How Precise Pipeline Measurements Prevent Structural Failures

Pipelines are vital infrastructure for transporting water, gas, and oil over extensive distances, but their failures pose environmental, economic, and safety hazards. Maintaining their integrity depends on accurate measurement tools such as geometry pipeline solutions, which facilitate effective monitoring and help prevent failures. Detecting early signs of issues like corrosion or pressure fluctuations enables targeted repairs, thereby prolonging pipeline lifespan. Modern digital technologies and remote sensors allow for the real-time monitoring of pipeline performance, which is especially important for aging systems. Industry standards now demand more extensive monitoring, where advanced instruments are crucial for preventing accidents, reducing costs, and protecting public safety.

Table of Contents

The Importance of Accurate Measurements

Precision in pipeline measurements is critical for operators striving to maintain safety and continuity of service. Each pipeline segment is subject to continuous stress from internal flow dynamics, temperature fluctuations, and external forces such as soil movement or construction activities. Measuring critical factors like internal pressure, flow velocity, and wall thickness at regular intervals empowers engineers to make data-backed decisions and address wear or damage before it puts the system at risk. Tools such as a geometry tool pipeline are particularly valuable in this process, as they provide detailed internal assessments that help identify defects, corrosion, or deformation. An illustrative example is the Korea Research Institute of Standards and Science (KRISS), which developed a real-time pipeline monitoring platform to provide early warnings and proactively mitigate threats, ultimately reducing incidents and extending asset life.

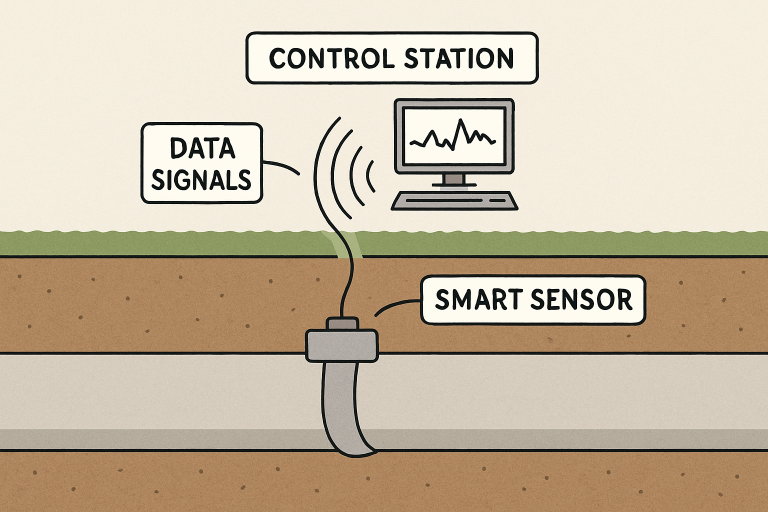

Advanced Monitoring Technologies

The emergence of sophisticated monitoring technologies has revolutionized the pipeline industry. Acoustic fiber optic systems deliver round-the-clock insights into pipeline conditions by detecting stress signals indicative of problems such as material fatigue or wire breaks in prestressed concrete pipeline structures. Recent systems are capable of locating breaks in near real-time, providing pipeline owners with actionable data before minor issues escalate into failures. These advancements not only improve safety but also streamline asset management practices, allowing maintenance teams to allocate resources where they are needed most, thus reducing costs associated with unplanned outages or emergency repairs.

AI and Machine Learning in Pipeline Safety

Artificial intelligence (AI) and machine learning (ML) are rapidly changing the landscape of pipeline threat detection. By capturing and interpreting vast quantities of sensor data, AI-powered platforms can differentiate between benign vibrations and those that signal genuine danger—whether from construction, seismic activity, or malicious interference. These systems learn to recognize unique patterns, improving the accuracy of event localization and reducing false positives. Recent research demonstrates how AI-based sensing methodologies dramatically enhance both the precision and response time of energy transport safety operations, moving the industry toward risk prediction and prevention rather than mere incident response.

Proactive Maintenance Strategies

Maintenance strategies, guided by robust measurement data, allow pipeline operators to shift from traditional time-based schedules to condition-based and reliability-centered frameworks. This proactive approach has delivered measurable benefits for large-scale utilities—preventing structural failures, avoiding service disruptions, and optimizing the frequency and scope of maintenance interventions. For example, aviation-inspired reliability-centered maintenance (RCM) processes have been adapted for water pipeline networks, resulting in fewer unexpected breakdowns and substantial lifecycle cost savings. The transition to predictive maintenance is helping operators meet evolving regulatory requirements and secure long-term operational resilience.

Challenges in Measurement and Monitoring

Despite significant progress, several challenges remain. It is often difficult to distinguish between strain caused by pipeline installation and that induced later due to shifting land, temperature changes, or mechanical impacts. Sensor placement and calibration are critical factors—incorrect installation or misinterpretation of data can lead to oversight. Industry professionals must continuously adapt, leveraging their expertise and ongoing advancements in monitoring methodologies to overcome these obstacles and ensure reliable, accurate pipeline surveillance.

Conclusion

Accurate, high-frequency pipeline measurements are at the heart of safe, efficient, and sustainable pipeline operations. With advanced technologies such as acoustic monitoring, AI-driven analytics, and reliability-centered maintenance strategies, the industry is equipped to identify and resolve risks before they turn into disasters. As pipeline networks age and demands grow, continuous investment in precision measurement and monitoring innovation will be vital to future-proofing these indispensable systems for generations to come.