The Future of Advanced Manufacturing: Materials and Precision

Table of Contents

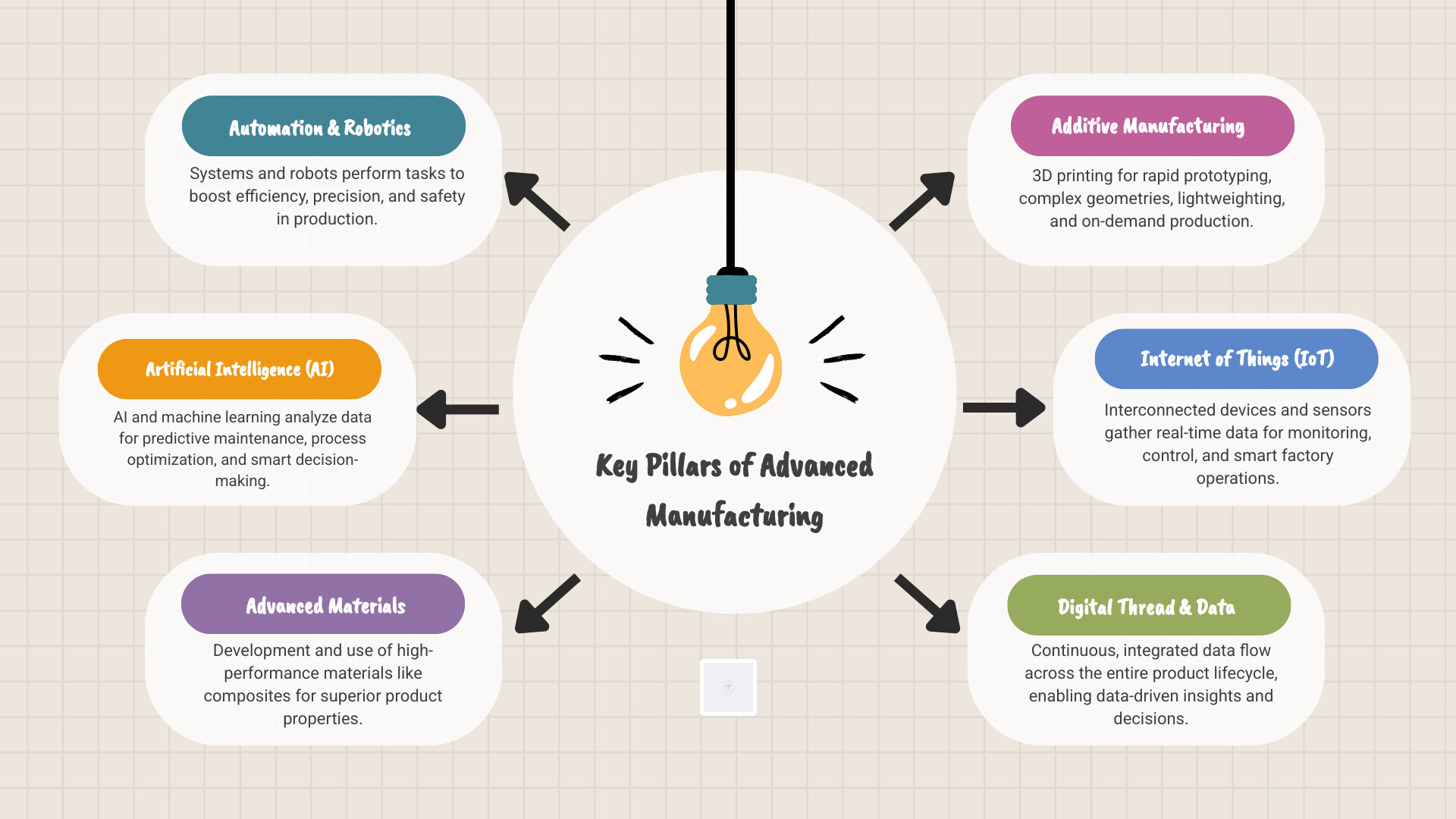

Core Technologies Powering the Next Industrial Wave

The way we make things is changing fast. We are in a new industrial revolution. This is called advanced manufacturing. It uses smart technologies and new processes. These make production more efficient and flexible.

The way we make things is changing fast. We are in a new industrial revolution. This is called advanced manufacturing. It uses smart technologies and new processes. These make production more efficient and flexible.

This shift is important for businesses everywhere. It helps them innovate. It also allows them to stay competitive globally. In this extensive guide, we will explore the exciting world of advanced manufacturing. We will see how it differs from older methods.

We will look at the key technologies that drive this change. A big part of this revolution involves new materials and very precise ways of making things. For example, advancements in Advanced composites manufacturing are changing what products can do. We will dive into these innovations. We will also examine how they impact different industries, from cars to medical devices.

The essence of advanced manufacturing lies in its adoption of groundbreaking technologies that transform every stage of the production lifecycle. We are moving beyond traditional, labor-intensive processes towards highly automated, intelligent, and interconnected systems. This wave is characterized by the seamless integration of automation, artificial intelligence (AI), the Internet of Things (IoT), and the “digital thread” – a continuous, connected data flow that spans design, production, and service. These elements work in concert to create factories that are not only more efficient but also more adaptable and responsive to market demands.

Additive Manufacturing (3D Printing)

One of the most technologies in advanced manufacturing is additive manufacturing, commonly known as 3D printing. Unlike traditional subtractive methods that remove material from a larger block, additive manufacturing builds objects layer by layer from a digital design. This capability open ups unprecedented design freedom, allowing for the creation of complex geometries, intricate internal structures, and customized parts that were previously impossible or prohibitively expensive to produce.

The benefits are profound. For instance, it enables rapid prototyping, allowing engineers to quickly test and iterate designs. It facilitates lightweighting, as parts can be designed with optimal material distribution, reducing weight without compromising strength – a critical advantage in industries like aerospace and automotive. Furthermore, additive manufacturing supports on-demand production, minimizing waste and inventory costs, and enabling localized manufacturing closer to the point of need. The adoption rate is significant; we see that approximately 44% of Canadian manufacturers use additive manufacturing (3D printing) technologies, demonstrating its growing importance across the industrial landscape. This technology is changing everything from medical implants to rocket components, enabling innovation at an accelerated pace.

Automation, Robotics, and AI

Automation and robotics are no longer confined to repetitive tasks on assembly lines; they are becoming increasingly intelligent and versatile thanks to advancements in AI. Industrial robots continue to handle heavy lifting and high-volume production with precision and speed. However, a new generation of collaborative robots, or cobots, is emerging, designed to work safely alongside human operators, augmenting their capabilities rather than replacing them entirely. This human-robot collaboration improves flexibility and efficiency in dynamic production environments.

AI is the brain behind much of this automation, enabling robots and machines to learn, adapt, and make decisions. AI-powered systems facilitate predictive maintenance, analyzing sensor data to anticipate equipment failures before they occur, minimizing downtime and optimizing operational efficiency. AI also drives quality control, identifying defects with greater accuracy and speed than human inspection. The global race for AI talent underscores its importance; Canada, for example, is recognized as #6 globally for AI skill penetration rate, highlighting the critical role of AI expertise in shaping the future of manufacturing. Innovations like the world’s first self-driving forklift, created by OTTO Motors in Ontario, exemplify how AI and robotics are improving efficiency and safety on factory floors globally. These intelligent systems are paving the way for “lights-out factories” where production can run autonomously 24/7, maximizing output and reducing operational costs.

The Digital Thread: IoT, Big Data, and Digital Twins

At the heart of advanced manufacturing’s intelligence is the “digital thread,” a seamless, integrated flow of data across the entire product lifecycle. This is powered by the Internet of Things (IoT), which connects machines, sensors, and systems across the factory floor and beyond. IoT devices collect vast amounts of data – Big Data – on everything from machine performance and material flow to environmental conditions.

This data is then analyzed using advanced analytics and AI to provide real-time monitoring, offering unprecedented visibility into operations. The concept of Smart Manufacturing leverages this digital thread to optimize processes, predict outcomes, and make data-driven decisions. A critical component of the digital thread is the “digital twin,” a virtual replica of a physical product, process, or system. Digital twins allow for sophisticated process simulation, enabling manufacturers to test scenarios, optimize performance, and identify potential issues in a virtual environment before implementing changes in the physical world. This not only saves time and resources but also significantly reduces risks.

The digital thread also extends to cybersecurity, as interconnected systems require robust protection against cyber threats. Ensuring the integrity and security of this data flow is paramount for maintaining operational continuity and protecting intellectual property. Furthermore, the push towards decentralized systems within the digital thread allows for more agile and resilient manufacturing networks, capable of adapting to disruptions and evolving market demands.

The Convergence of Advanced Materials and Precision Processes

The leap forward in advanced manufacturing isn’t solely about digital technologies; it’s equally about the materials we use and the unparalleled precision with which we shape them. Material science is at the forefront of this revolution, delivering high-performance polymers, composites, and other engineered substances that redefine what’s possible. These materials, combined with cutting-edge precision processes, enable the creation of high-tolerance parts with superior strength, durability, and functional properties, all while maintaining stringent quality control standards.

Innovations in Composite Materials

Composite materials are a cornerstone of advanced manufacturing, offering a combination of properties that traditional materials simply cannot match. Carbon fiber, for instance, is renowned for its exceptional strength-to-weight ratio, making it an ideal choice for applications where weight reduction is critical without sacrificing structural integrity. High-performance polymers further expand the possibilities, providing excellent chemical resistance, thermal stability, and electrical insulation properties.

These materials are not just stronger or lighter; they are engineered with specific applications in mind, allowing for tailor-made solutions. From the aerospace industry, where lightweight composites are crucial for fuel efficiency, to the automotive sector, where they contribute to vehicle performance and safety, these innovations are transformative. The development and application of these novel materials are continuously pushing boundaries. Companies engaged in advanced composites manufacturing are at the leading edge, developing and integrating these materials into complex structures, enabling breakthroughs in various industries. This continuous innovation in materials science is fundamental to achieving the next generation of product performance and efficiency.

The Critical Role of Precision in Advanced Manufacturing

Even the most advanced materials require equally advanced processes to open up their full potential. Precision is paramount in modern manufacturing, ensuring that components meet exact specifications, function flawlessly, and integrate seamlessly into larger systems. Computer Numerical Control (CNC) machining remains a vital technology, offering unparalleled accuracy and repeatability in shaping complex parts from a wide array of materials, including advanced composites and metals.

Beyond traditional machining, techniques like laser cutting, waterjet cutting, and electrical discharge machining (EDM) provide even finer control and the ability to work with incredibly hard or delicate materials. These precision processes are essential for producing high-tolerance components required in sensitive applications such as medical devices, where even microscopic deviations can have significant consequences, or in electronics fabrication, where miniaturization demands extreme accuracy. The expertise in delivering such exacting standards is a hallmark of leading manufacturers. For example, specialized providers like Staub Precision advanced manufacturing excel in producing parts with the tightest tolerances, ensuring optimal performance and reliability across diverse industries. This commitment to precision is not just about meeting specifications; it’s about guaranteeing the quality, safety, and functionality of the final product.

The Global Impact of Advanced Manufacturing

The ripple effects of advanced manufacturing extend far beyond factory walls, influencing global economies, environmental policies, and national security. It acts as a powerful economic driver, fostering innovation and competitiveness while simultaneously presenting opportunities to address critical global challenges. Governments and industries worldwide recognize its transformative potential, leading to concerted efforts in research, development, and adoption.

Driving Sustainability and Green Initiatives

Advanced manufacturing offers a crucial pathway towards a more sustainable future. By integrating smart technologies and processes, manufacturers can significantly reduce their environmental footprint. Key strategies include embracing the circular economy, which focuses on minimizing waste through product design, reuse, recycling, and remanufacturing. Energy efficiency is another major focus, with advanced processes designed to consume less power and optimize resource utilization. For instance, the U.S. manufacturing sector accounts for approximately one-third of the nation’s primary energy usage and 30 percent of energy-related GHG emissions, highlighting the immense potential for advanced manufacturing to drive significant reductions.

The development of green supply chains, from sourcing sustainable raw materials to optimizing logistics, is also gaining traction. Furthermore, research into biodegradable and recyclable materials is enabling the creation of products that are environmentally friendly throughout their lifecycle. This commitment to sustainability is not just an ethical imperative but also an economic advantage, as consumers and regulations increasingly favor eco-conscious production.

Economic Drivers and Global Competitiveness

Advanced manufacturing is a powerful engine for economic growth and a critical determinant of global competitiveness. Its adoption leads to:

- Increased productivity: Automated and intelligent systems produce more with fewer resources.

- Higher-paying jobs: The demand for skilled technicians, engineers, and data scientists creates new, high-value employment opportunities.

- Market expansion: The ability to innovate rapidly and customize products opens up new markets and customer segments.

- Innovation leadership: Countries and companies that invest in advanced manufacturing become leaders in technological development.

The economic impact is substantial. For example, the manufacturing sector in the EU generates €2.2 trillion in value added, equal to 23.7% of the EU business economy, underscoring its foundational role. Nations are actively developing strategies to capitalize on these benefits. The United States, for instance, has outlined a comprehensive National Strategy for Advanced Manufacturing to grow the economy, create quality jobs, and strengthen supply chains. Similarly, initiatives like Canada’s Next Generation Manufacturing Canada (NGen) are designed to strengthen the competitiveness and growth potential of the advanced manufacturing ecosystem, supporting technology adoption and workforce development. These strategic investments are vital for securing a nation’s economic future in an increasingly competitive global landscape.

Fortifying Supply Chains and National Security

The recent global disruptions have starkly highlighted the vulnerabilities in traditional supply chains, making supply chain resilience a top priority. Advanced manufacturing plays a pivotal role in fortifying these critical networks and enhancing national security. Strategies like onshoring and reshoring production, bringing manufacturing capabilities back to domestic soil, reduce reliance on distant and potentially unstable sources. This decentralization and localization of production, often enabled by flexible advanced manufacturing technologies, can mitigate risks associated with geopolitical tensions, natural disasters, or pandemics.

Improved supply chain visibility, achieved through the digital thread and real-time data analytics, allows manufacturers to track goods, anticipate disruptions, and respond swiftly. For defense applications, advanced manufacturing ensures the domestic production of critical components and equipment, reducing dependence on foreign suppliers and safeguarding sensitive technologies. The ability to quickly produce specialized parts, from advanced weaponry to essential infrastructure, is a strategic asset. In environments demanding extreme reliability and durability, the use of rugged advanced manufacturing equipment is paramount, ensuring that critical production capabilities can withstand challenging conditions and maintain operational integrity. This focus on domestic capabilities and robust equipment directly contributes to a nation’s strategic autonomy and readiness.

Charting the Future: Workforce, Challenges, and Trends

As advanced manufacturing continues its rapid evolution, it brings with it a new set of challenges and opportunities. The future of work is being reshaped, requiring a fundamental shift in workforce skills and educational paradigms. While the benefits are clear, the path to widespread adoption is not without problems, necessitating strategic planning and collaborative efforts.

Bridging the Skills Gap in Advanced Manufacturing

One of the most pressing challenges facing the advanced manufacturing sector is the widening skills gap. The shift from manual labor to highly technical roles demands a workforce proficient in areas like data analytics, robotics programming, AI, cybersecurity, and advanced materials science. Traditional education and training systems often lag behind these rapidly evolving requirements, leading to a significant shortage of qualified talent. Projections indicate a severe deficit, with the United States potentially facing more than two million unfilled manufacturing jobs by 2030 if current trends continue.

To bridge this gap, a multi-faceted approach is essential. This includes strengthening STEM (Science, Technology, Engineering, and Mathematics) education from an early age, implementing robust upskilling and reskilling programs for existing workers, and developing specialized curricula for new job roles. The new landscape requires a diverse array of professionals, from data scientists who can interpret the vast amounts of information generated by smart factories, to robotics technicians who can program and maintain complex automated systems, and materials engineers who can innovate with advanced composites and polymers. Collaborative efforts between educational institutions, industry, and government are crucial to developing a pipeline of skilled workers ready to drive the next industrial wave.

Overcoming Challenges and Embracing Future Trends in Advanced Manufacturing

While the promise of advanced manufacturing is immense, its widespread adoption faces several challenges. The high initial cost of implementing advanced technologies, such as industrial robots, specialized additive manufacturing equipment, and integrated digital systems, can be a significant barrier, especially for small and medium-sized enterprises (SMEs). The complexity of integrating disparate systems and ensuring seamless data flow across the digital thread also poses technical and organizational problems. Moreover, data security and privacy concerns become paramount as more processes become digitized and interconnected, requiring robust cybersecurity measures.

Despite these challenges, the future of advanced manufacturing is bright, driven by exciting emerging trends. In-space manufacturing, for example, envisions producing goods and structures in orbit, leveraging unique microgravity environments and reducing the need for Earth-based launches. Human-centered automation focuses on designing systems where humans and machines collaborate more intuitively and effectively, enhancing worker safety and productivity. Public-private partnerships are becoming increasingly vital, pooling resources and expertise to accelerate research, development, and technology transfer, addressing shared challenges and fostering innovation on a larger scale. These collaborations are key to navigating the complexities and open uping the full potential of advanced manufacturing.

Frequently Asked Questions

How does advanced manufacturing differ from smart manufacturing?

Advanced manufacturing is a broad umbrella term encompassing any innovative technology or process that improves manufacturing capabilities, efficiency, and product quality. It includes a wide range of advancements from new materials and production methods (like additive manufacturing) to sophisticated automation. Smart manufacturing, on the other hand, is a specific, crucial component of advanced manufacturing. It focuses on using data, artificial intelligence, the Internet of Things, and network connectivity to create intelligent, adaptable, and self-optimizing production systems. Essentially, all smart manufacturing is advanced manufacturing, but not all advanced manufacturing necessarily involves the full scope of smart, interconnected systems.

How can small and medium-sized manufacturers (SMMs) get started?

For small and medium-sized manufacturers (SMMs), the journey into advanced manufacturing can seem daunting, but it’s crucial for long-term competitiveness. A practical approach involves starting with a specific problem or bottleneck within their current operations rather than attempting a complete overhaul. Leveraging government programs and support clusters, which often provide funding, training, and technical assistance, can be invaluable. Seeking partnerships with technology providers, research institutions, or even larger manufacturers can facilitate technology adoption and knowledge transfer. Given that SMMs comprise 98% of U.S. manufacturers and account for a significant portion of employment, their successful integration into advanced manufacturing is vital for the overall health of the industrial economy.

What industries are being most transformed by advanced manufacturing?

Advanced manufacturing is profoundly changing a wide array of industries, enabling unprecedented levels of innovation, efficiency, and customization. The aerospace and defense sectors are at the forefront, benefiting from lightweight, high-strength composite materials and additive manufacturing for complex components. The automotive industry is leveraging advanced robotics, AI, and new materials for electric vehicles and autonomous driving systems. Healthcare and medical devices are seeing breakthroughs in personalized implants, prosthetics, and drug delivery systems through 3D printing and precision manufacturing. Electronics manufacturing relies heavily on high-precision techniques and automation for miniaturization and complex circuitry. Finally, the energy sector is utilizing advanced materials and processes for more efficient renewable energy systems and advanced power generation components.

Conclusion

The journey into advanced manufacturing is not merely an upgrade of existing processes; it is a fundamental reimagining of how we design, produce, and deliver goods. We have explored how the convergence of digital technologies—from AI and robotics to the digital thread—with groundbreaking material science and unparalleled precision is ushering in a new era of industrial capability. This revolution promises not only improved economic competitiveness and higher-value jobs but also critical pathways towards greater sustainability, supply chain resilience, and national security. While challenges such as the skills gap and initial investment costs remain, the collaborative spirit of public-private partnerships and continuous innovation will pave the way forward. The future of making things is intelligent, adaptable, and deeply interconnected, and we are excited to be part of this transformative journey.