How Pipe Cutting & Beveling Shapes the Future of Welding Quality

Table of Contents

- 1 Pipe Preparation Matters in Welding Projects

- 2 How Cutting Techniques Affect Weld Quality

- 3 The Art and Science of Beveling

- 4 Common Errors and Their Consequences

- 5 Modern Tools and Technology in Pipe Preparation

- 6 Quality Assurance: Inspection and Standards

- 7 Training and Best Practices for Better Results

- 8 Real-World Impact: Case Studies and Industry Data

- 9 Conclusion: The Path to Welding Success

Pipe Preparation Matters in Welding Projects

Welding is the backbone of key energy, infrastructure, and manufacturing sectors. The success of these projects relies not just on skilled welders but on the foundation set by precise pipe preparation. Every strong weld begins with perfectly cut and beveled pipes. This fundamental step ensures the tight fit-up, clean edges, and correct geometry for reliable, high-integrity welds. When starting with well-prepared materials, the risk of structural weaknesses and project delays significantly decreases. A trusted resource in optimizing this process is Tulsa pipe solutions, which offer advanced tools and services to ensure the highest standards from the start. Companies relying on expert pipe preparation lay the groundwork for efficient workflows, minimized rework, and safer outcomes across industrial projects.

How Cutting Techniques Affect Weld Quality

Precision pipe cutting is more complex than a simple division of metal. Modern approaches—such as cold and plasma cutting—are designed to maintain pipe shape and material properties while achieving impeccable accuracy. These advanced methods reduce heat-affected zones, eliminate the risk of edge hardening, and guarantee square, even cuts. Quality cuts are essential for uniform welds and proper fusion, preventing many types of costly weld defects. The right technology supports fabricators and protects the integrity of entire pipeline networks, pressurized systems, and critical infrastructure. Choosing a cutting method suited for specific material types, wall thicknesses, and project demands is key to maximizing weld quality and minimizing risk.

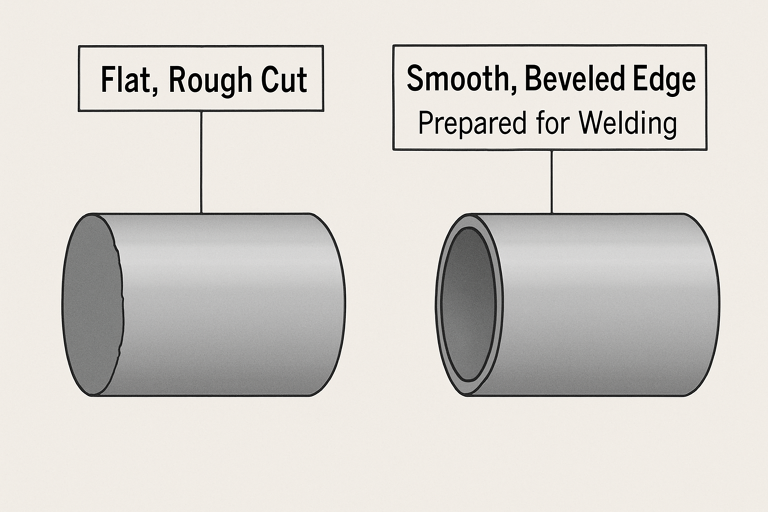

The Art and Science of Beveling

Beveling transforms a standard pipe end into a surface optimized for welding. Traditional and automated beveling machines remove material at a precise angle—often 30 to 37.5 degrees—to create a clean “V” or “U” groove. This geometry makes it easier for welders to penetrate with the root pass and avoid lack-of-fusion defects fully. Depending on codes, materials, or joint configuration, each application may require a different bevel profile or angle. Skilled operators and advanced beveling tools make it possible to keep tolerances tight, waste low, and consistency high, even on demanding projects.

Common Errors and Their Consequences

- Uneven Bevels: Risk of incomplete fusion and excessive weld reinforcement, weakening the joint.

- Poorly Cut Edges: Jagged or out-of-square cuts complicate fit-up, leading to gaps, misalignments, and ultimately, poor-quality welds.

- Incorrect Angle: Using angles too steep or too shallow often results in subpar weld penetration, increased porosity, or potential leaks.

- Inadequate Cleaning: Failing to remove oils, rust, or debris from cut and beveled surfaces introduces contaminants that cause porosity and inclusions.

Modern Tools and Technology in Pipe Preparation

Technological advancements have revolutionized how industry professionals approach pipe cutting and beveling. Innovations such as CNC machines, digital calipers, and automated orbital systems dramatically increase accuracy, efficiency, and safety. These solutions allow continuous monitoring and adjustment, reducing human error and variability. Automated bevelers and digital inspection tools achieve levels of repeatability that were previously unattainable with manual labor alone. Integrating these systems is vital for complex infrastructure and energy projects where precision and traceability are non-negotiable.

Quality Assurance: Inspection and Standards

Comprehensive quality control is the backbone of robust pipeline assembly. Dimensional verification, angle measurement, and rigorous cleaning checks confirm that every pipe segment matches project and industry standards before welding. Organizations adhere to codes like those set by the American Society of Mechanical Engineers (ASME) and local regulatory authorities for safety and quality assurance. Frequent inspections catch issues early, prevent failures, and ultimately drive up the longevity and reliability of welded joints.

Training and Best Practices for Better Results

Even with the best equipment available, human expertise remains irreplaceable. Continuous hands-on training and industry certifications ensure that operators stay current with advancements in machinery and evolving standards. Regular workshops and refresher courses effectively eliminate common pitfalls and optimize productivity on-site. Industry leaders foster a learning culture, empowering workers to utilize classic techniques and cutting-edge tools while upholding a commitment to quality and safety.

Real-World Impact: Case Studies and Industry Data

Adequate pipe preparation has tangible benefits documented throughout the welding industry. Reducing cutting or beveling errors by as little as 1% in large-scale pipeline construction can translate into hundreds of thousands of dollars saved by minimizing rework and project slowdowns. Reliable preparation means welders spend less time fixing alignment issues, creating a safer, more efficient work environment. Investments in modernized equipment and skilled training can yield exponential safety, quality, and long-term project cost management returns.

Conclusion: The Path to Welding Success

The importance of precise pipe cutting and beveling cannot be overstated. They serve as the foundation for every strong, dependable weld and are crucial for maintaining the highest quality and safety standards in the welding industry. By combining advanced technology, thorough inspections, and ongoing operator training, teams can deliver exceptional project results—setting a new standard for productivity, safety, and long-term performance in every weld, one accurate cut, and bevel at a time.