How to Master Construction Material Tracking

Table of Contents

- 1 The High Cost of Inefficiency: Core Challenges in Material Tracking

- 2 The Technology-Driven Solution: From Barcodes to Real-Time Visibility

- 3 Implementing a Robust Strategy for AI Construction Material Tracking

- 4 Leveraging AI for Advanced Insights and Data Accuracy

- 5 The Future of Material Management: What’s Next?

- 6 Frequently Asked Questions about Construction Material Tracking

- 7 Conclusion

The High Cost of Inefficiency: Core Challenges in Material Tracking

In the demanding world of construction, materials are the bedrock of every project, yet their management often presents a labyrinth of challenges. From the moment materials are ordered to their final installation, a complex journey unfolds, riddled with potential pitfalls that can erode profitability and trigger costly delays. Consider the staggering statistic: the construction industry faces losses estimated at up to $1 billion annually due to theft and waste alone. These aren’t just minor inconveniences; they represent significant drains on resources, impacting budgets, timelines, and ultimately, a project’s success.

We understand that mastering material tracking is no longer a luxury but a necessity for any construction enterprise aiming for efficiency and financial stability. Traditional, often manual, methods simply cannot keep pace with the scale and complexity of modern projects, leaving teams vulnerable to inefficiencies and unexpected setbacks.

This comprehensive guide will steer the intricate landscape of construction material tracking. We will dig into the primary challenges that plague project sites, explore how cutting-edge technologies like barcodes, QR codes, and RFID are revolutionizing inventory management, and uncover the transformative power of real-time data. Furthermore, we’ll examine how the evolution of AI construction material tracking is moving beyond basic alerts to provide deep, actionable insights and proactive security. Our aim is to equip you with the knowledge and strategies needed to streamline your operations, reduce waste, and safeguard your investments, ensuring your projects are delivered on time and within budget.

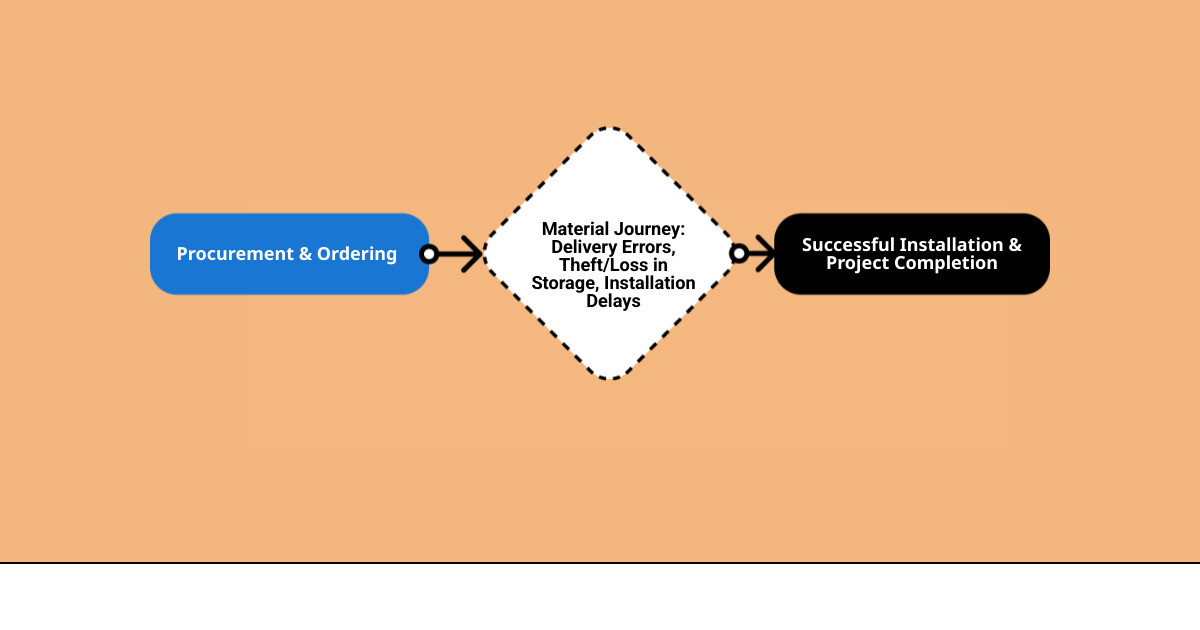

The journey of construction materials, from procurement to installation, is fraught with potential obstacles that can significantly impact a project’s success. We’ve identified several primary challenges in construction material tracking that frequently plague project sites, leading to costly inefficiencies.

One of the most immediate and impactful challenges is theft and loss. Construction sites, often sprawling and open, are unfortunately prime targets for criminals. Raw materials, tools, and even heavy machinery can disappear, leading to direct financial losses and project delays. Beyond outright theft, materials can be misplaced, damaged, or simply deteriorate due to improper storage, contributing to significant waste.

This leads directly to project delays and budget overruns. When a critical material is missing, damaged, or simply cannot be located, work grinds to a halt. Crews stand idle, waiting for replacements, pushing back schedules and incurring additional labor costs. These delays can trigger contractual penalties and erode profit margins. The ripple effect of a single missing material can be surprisingly extensive, creating a “domino effect” across various project phases.

Inaccurate inventory is another pervasive issue. Without precise knowledge of what materials are on site, their quantities, and their exact locations, companies face a constant struggle. This leads to over-ordering (tying up capital and storage space) or under-ordering (causing delays and urgent, expensive last-minute procurements). This lack of clarity also results in wasted labor as workers spend valuable time searching for items that may or may not be there.

Furthermore, there’s often poor visibility across the supply chain. Materials might be in transit, at a vendor’s warehouse, or already delivered to a laydown yard, but without a unified tracking system, their exact status remains a mystery. This lack of transparency extends to on-site storage and handling issues, where materials are not stored optimally for security, accessibility, or protection from the elements.

Finally, communication gaps between field and office exacerbate these problems. The site manager might be unaware of a delayed delivery until it’s too late, or the procurement team might not receive timely updates on material consumption, leading to forecasting errors.

Why Traditional Methods Fall Short

For too long, the construction industry has relied on traditional, often rudimentary, methods for material tracking. These approaches, while seemingly simple, are inherently inefficient and prone to error, making them ill-suited for the demands of modern construction.

Manual tracking and paper-based logs are perhaps the most common culprits. Workers jot down deliveries and usage on clipboards, which are then manually transferred to spreadsheets. This process is incredibly time-consuming and creates immediate data lag. Spreadsheet limitations further hinder effective management; while useful for basic data organization, they struggle with real-time updates, complex inventory relationships, and multi-user access across a dynamic construction site.

The biggest drawback of these methods is the pervasive issue of human error. Illegible handwriting, incorrect entries, forgotten updates, or lost paperwork are all too common, leading to inaccurate data that can be more detrimental than no data at all. This results in a fundamental lack of real-time data, meaning decisions are often based on outdated information, rather than the current reality on the ground.

Moreover, these traditional methods demonstrate a clear difficulty scaling for large projects. What might work for a small residential build quickly breaks down on a commercial skyscraper or an industrial plant with thousands of unique material types and complex logistics. They simply lack the sophistication to manage vast inventories and intricate supply chains, making it impossible to proactively prevent theft or optimize material flow across a large, multi-phase project. As a result, companies are often left reactive, rather than proactive, in their material management.

The Financial and Operational Impact

The cumulative effect of these challenges is a significant drain on a project’s financial health and operational efficiency. The “low-margin” nature of the construction industry means that even small inefficiencies can quickly escalate into substantial losses.

Here are some of the common financial and operational drains we observe:

- Cost of replacing stolen/lost materials: This is a direct hit to the budget, often requiring expedited, more expensive purchases to avoid further delays.

- Labor costs for searching for items: When crews spend hours hunting for specific components, those hours are non-productive and directly impact the project’s labor budget.

- Penalties for project delays: Missed deadlines due to material shortages can trigger contractual penalties, further eroding profitability.

- Increased insurance premiums: A history of theft and loss can lead to higher insurance rates for future projects.

- Budget reconciliation nightmares: Reconciling material costs at the end of a project becomes a complex, time-consuming task when initial tracking was poor, leading to disputes and further administrative overhead.

- Reduced productivity: Disorganized sites and missing materials create frustration and reduce overall worker morale and efficiency.

- Damaged client relationships: Delays and budget overruns ultimately impact client satisfaction and can harm a company’s reputation, affecting future business opportunities.

These impacts highlight why robust material tracking is not just a logistical concern, but a strategic imperative for financial health and competitive advantage.

The Technology-Driven Solution: From Barcodes to Real-Time Visibility

Recognizing the immense challenges posed by traditional methods, the construction industry is increasingly embracing technology to revolutionize material tracking. We’ve seen a significant evolution in tracking capabilities, moving from basic identification to sophisticated, real-time visibility.

The journey often begins with foundational technologies like barcodes. These simple, scannable labels allow for basic check-in and check-out of materials, providing a digital record of movement. While a vast improvement over paper, barcodes require a direct line of sight for scanning and can be limited in the amount of data they store.

Stepping up in capability, QR codes offer an improvement. They can store significantly more information than traditional barcodes, including serial numbers, specifications, and even links to digital documentation. They are also more resilient to damage and can be scanned quickly by most smartphones, making them highly practical for field use. A Motorola-endorsed survey found that an impressive 67% of companies plan to use mobile tracking to manage inventory, indicating a clear shift towards these accessible technologies.

For automated, non-line-of-sight scanning, RFID (Radio-Frequency Identification) tags are a game-changer. These tags emit radio signals that can be read by a scanner from a distance, even if the tag is obscured. This allows for rapid inventory counts of entire pallets or container loads without manual scanning, significantly boosting efficiency. While construction projects in Malaysia, for example, are noted for still largely using manual practices and lacking RFID implementation, the global trend points towards its increasing adoption.

For high-value equipment and critical deliveries, GPS (Global Positioning System) tracking is invaluable. Attaching GPS trackers to machinery or even large material shipments allows for continuous monitoring of their location, providing peace of mind and aiding in recovery if theft occurs.

The true power of these technologies is releaseed when combined with mobile technology and apps for field data capture. Smartphones and tablets, equipped with specialized applications, become powerful tools in the hands of field teams, enabling them to record, update, and access material information instantly from anywhere on the job site.

The Power of Real-Time Data

The shift from static, retrospective tracking to dynamic, real-time data is one of the most transformative benefits of modern material tracking technologies. Imagine having an immediate, accurate pulse on every material on your job site.

With real-time tracking, we gain:

- Immediate updates on material status: Know instantly if a material has been received, moved to a specific zone, is currently in use, or has been installed. This eliminates guesswork and ensures everyone is working with the most current information.

- Proactive alerts for low stock or delivery delays: Systems can be configured to send automated notifications when inventory levels drop below a certain threshold or when a scheduled delivery is delayed. This allows project managers to address potential issues before they impact the schedule.

- Improved decision-making for project managers: Access to real-time data empowers project managers to make informed decisions about resource allocation, scheduling adjustments, and procurement, optimizing workflows and preventing costly bottlenecks.

- Improved team accountability: When every material movement is logged and traceable, it fosters a culture of accountability among team members, reducing loss and encouraging careful handling.

This level of insight allows companies to improve margins by 30% through confident procurement, knowing exactly what they have and what they truly need. It also helps cut T&M/Change Order Processing Time by 50%+, as accurate material usage data is readily available for documentation.

How Mobile Technology Empowers Field Teams

Mobile technology is not just a convenience; it’s a critical enabler for effective construction material tracking. By putting powerful tools directly into the hands of field teams, we bridge the historical gap between on-site activities and office-based management.

- Easy data entry via smartphones/tablets: Intuitive mobile apps allow workers to quickly scan barcodes or QR codes, input quantities, and update material statuses with just a few taps. This drastically reduces the time spent on administrative tasks and minimizes the potential for human error associated with manual paperwork.

- Capturing high-resolution, time-stamped photos for proof of delivery and quality checks: Mobile devices allow teams to instantly document material deliveries, condition upon arrival, and installation progress. These time-stamped photos provide irrefutable proof, aiding in dispute resolution and ensuring quality control. For instance, if a material arrives damaged, a quick photo upload can initiate the replacement process immediately.

- Instant communication through integrated messaging: Many modern tracking apps include built-in communication features, enabling field teams to quickly flag issues, request information, or coordinate with suppliers and office staff directly within the platform. This streamlines communication and ensures all relevant parties are informed in real-time.

- Offline capabilities for remote sites: Crucially, many mobile tracking solutions are designed to work offline, syncing data once an internet connection is re-established. This ensures that tracking remains uninterrupted even in remote areas of a construction site where connectivity might be sporadic.

- Reducing the gap between on-site events and office updates: With mobile technology, the office gains immediate visibility into what’s happening on the ground. This real-time synchronization means that procurement, accounting, and project management teams are always working with the most up-to-date information, fostering better collaboration and responsiveness.

The impact is clear: mobile technology transforms every worker with a smartphone into a data collection point, dramatically enhancing the accuracy and timeliness of material tracking.

Implementing a Robust Strategy for AI Construction Material Tracking

Implementing a robust strategy for construction material tracking goes beyond simply adopting new technology; it requires a holistic approach that integrates processes, people, and advanced solutions. Our team helps clients build a comprehensive system, ensuring it’s not just about the technology, but how it transforms the entire project lifecycle.

Planning Your Inventory Infrastructure

A well-planned inventory infrastructure is the backbone of effective material tracking. Without it, even the most advanced technology will struggle to deliver its full potential.

- Defining material flow: We start by carefully mapping out the expected journey of every material, from its arrival on site to its final installation. This includes identifying all touchpoints and potential storage locations.

- Establishing clear laydown yards and storage zones: Organizing the physical space is paramount. Clearly designated and labeled laydown yards and secure storage zones ensure materials are placed logically, protected from theft and damage, and easily retrievable. This also aids in visual verification and inventory counts.

- Aligning delivery schedules with project timelines: Just-in-time (JIT) delivery is an ideal, but it requires precise coordination. We work to align material deliveries with the actual construction schedule, minimizing the need for extensive on-site storage and reducing the risk of materials sitting idle or deteriorating.

- Differentiating strategies for project types: Material tracking strategies must be custom to the specific nature of the project. Residential construction, with its often standardized materials and smaller scale, will have different needs than a large commercial development or a complex industrial project, which might involve custom-fabricated components and intricate logistics. For instance, tracking rebar on a residential foundation differs greatly from managing custom curtain wall panels for a high-rise.

- Creating a single source of truth for all stakeholders: Central to any robust infrastructure is a unified system where all material-related data resides. This “single source of truth” ensures that project managers, site supervisors, procurement teams, and even subcontractors are all accessing the same, up-to-date information, eliminating discrepancies and fostering seamless collaboration.

On-Site Best Practices and Supplier Management

Effective material tracking extends beyond planning; it requires diligent execution of best practices on-site and strategic engagement with suppliers.

- Standardized receiving process: Every material arriving on site should undergo a consistent receiving process. This involves verifying quantities against purchase orders, inspecting for damage, and immediately tagging and logging the materials into the tracking system. This initial step is crucial for data accuracy.

- Secure storage protocols for high-value items: High-value materials, such as copper wiring, specialized equipment, or custom-fabricated components, require improved security. This might include dedicated, locked storage containers, restricted access areas, or even the deployment of AI-powered surveillance units to monitor these zones specifically.

- Just-in-time delivery coordination: Working closely with suppliers to orchestrate just-in-time deliveries minimizes on-site clutter, reduces storage costs, and lowers the risk of theft or damage to materials that are sitting idle.

- Building strong, communicative supplier relationships: Effective material tracking is a collaborative effort. Proactive supplier relationship management is vital. By fostering transparent and communicative relationships, we can ensure suppliers understand project requirements, delivery windows, and quality expectations. This collaboration helps anticipate potential delays or issues and allows for quicker resolution. Companies like Matrak offer platforms that help connect global supply chains, enabling source-to-site tracking and communication with suppliers. For more insights on this, you can explore their solutions here.

- Integrating material tracking with project management software: The true power of modern tracking comes from its integration. Linking material tracking systems with broader project management software (like Procore or Autodesk Construction Cloud) improves overall project efficiency by providing a holistic view. This allows for automated updates to schedules based on material availability, better budget management, and streamlined communication across all project functions. For example, Matrak seamlessly integrates with various project management tools to create effortless workflows. You can learn more about their integrations here.

Measuring Success: Key Performance Indicators (KPIs)

To truly understand the impact of material tracking initiatives, we need to measure their effectiveness. Key Performance Indicators (KPIs) provide quantifiable metrics that highlight improvements and areas for further optimization.

Here are some essential KPIs for construction material tracking:

- Material availability rate: The percentage of required materials that are on-site and ready for use when needed. A high rate indicates efficient planning and tracking.

- Inventory accuracy percentage: The degree to which the recorded inventory matches the physical inventory on site. This directly reflects the reliability of the tracking system.

- Reduction in material waste: Measures the decrease in materials lost, damaged, or discarded. This directly correlates with cost savings and sustainability efforts.

- On-time delivery percentage: The proportion of material deliveries that arrive within the scheduled window. This is a critical indicator of supply chain reliability and coordination.

- Time saved searching for materials: Quantifies the reduction in unproductive labor hours spent by crews looking for items.

- Cost variance: Compares the actual cost of materials against the budgeted cost, highlighting the financial impact of efficient procurement and reduced waste.

KPI Before Tracking System After Tracking System Improvement Material Availability Rate 70% 95% 25% Inventory Accuracy Percentage 60% 90% 30% Reduction in Material Waste 15% 5% 10% On-Time Delivery Percentage 75% 92% 17% Time Saved Searching (per week) 10 hours 2 hours 80% Material Cost Variance (average) +8% -2% 10% These KPIs provide a clear picture of how material tracking initiatives contribute to cost savings, waste reduction, and overall project efficiency.

Leveraging AI for Advanced Insights and Data Accuracy

While traditional tracking technologies like barcodes and RFID provide valuable data, the true revolution in construction material tracking comes from leveraging Artificial Intelligence (AI). We’re moving beyond simple tracking to intelligent monitoring, where systems don’t just record data but analyze it, predict outcomes, and even act autonomously. This is where AI truly shines, enhancing both the insights we gain and the accuracy of the data collected.

Our AI-powered mobile surveillance units, for instance, provide a crucial layer of intelligence that static tracking systems cannot. They don’t just observe; they interpret. This enables us to ensure data quality and accuracy through automated verification, drastically reducing human error and providing a reliable source of truth. The evolution of AI construction material tracking has moved beyond simple alerts to provide deep, actionable insights.

Open uping Actionable Intelligence with AI

AI transforms raw data into meaningful, actionable intelligence, allowing project teams to make smarter decisions faster.

- Using AI Inspector to automatically verify material deliveries against purchase orders: Imagine a delivery truck arriving on site. Instead of a manual check, an AI-powered system can scan incoming materials, compare them against the digital purchase order, and automatically flag any discrepancies in quantity or type. This dramatically speeds up the receiving process and ensures accuracy from the moment materials arrive.

- Using natural language “Magic Search” to find specific video events in seconds: Need to find footage of a specific delivery, or when a certain piece of equipment was moved? AI-powered search capabilities allow users to simply type in queries like “blue truck unloading rebar” or “excavator moved to north corner,” and the system quickly retrieves relevant video events, saving hours of manual review.

- Generating automated reports on material movement and usage patterns: AI can analyze vast amounts of tracking data to identify trends, predict future material needs, and highlight inefficiencies in material handling. These automated reports provide valuable insights for optimizing logistics, reducing waste, and improving future project planning.

Proactive Security and Loss Prevention with AI

AI is also a powerful ally in enhancing site security and preventing material loss, offering a proactive approach that traditional surveillance cannot match.

- How our Virtual Guard feature uses AI to detect and deter theft in real-time: Our Virtual Guard system leverages AI to continuously monitor construction sites. It can differentiate between authorized personnel and potential intruders, detecting unusual activity or unauthorized entry into restricted areas. Upon detection, the system can trigger immediate alerts, activate on-site loudspeakers to deter intruders, or even initiate a live remote intervention, effectively acting as a digital security guard.

- Differentiating between authorized personnel and potential threats: AI is trained to recognize patterns of normal activity versus suspicious behavior. This allows it to minimize false alarms while focusing on genuine threats, ensuring security teams can respond effectively.

- Creating virtual perimeters (geofencing) around material storage areas: AI-powered systems can establish virtual boundaries around sensitive areas, such as high-value material storage. If any activity is detected within these geofenced zones outside of designated hours or by unauthorized individuals, an immediate alert is triggered.

- Using high-resolution, zoom-capable footage for incident investigation and case reporting: In the unfortunate event of theft or damage, the AI system provides crystal-clear, high-definition footage with zoom capabilities. This visual evidence is invaluable for incident investigation, insurance claims, and providing law enforcement with the necessary details for recovery and prosecution.

By integrating AI into material tracking and site security, we empower construction companies to not only monitor their assets but to actively protect them, minimizing losses and ensuring project continuity.

The Future of Material Management: What’s Next?

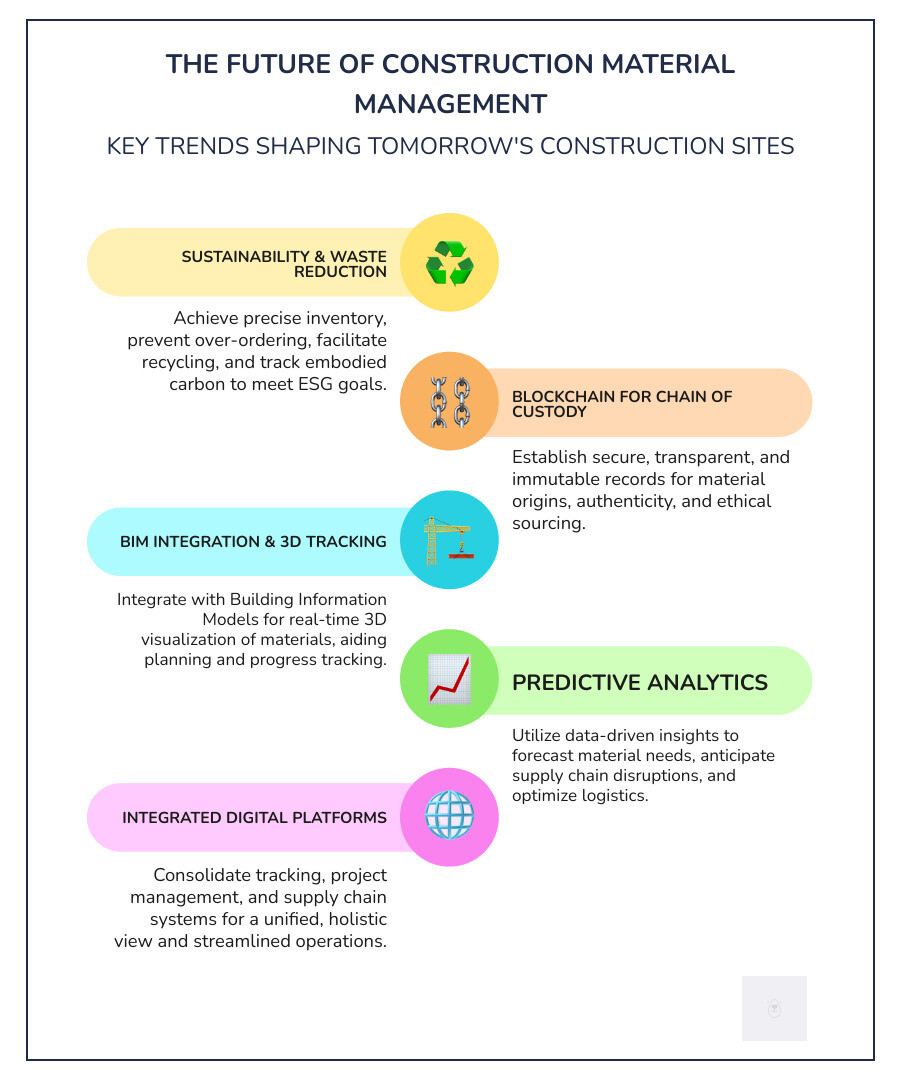

The landscape of construction material management is continuously evolving, driven by technological advancements and a growing emphasis on sustainability. We anticipate several key trends that will shape its future, pushing the boundaries of efficiency, transparency, and environmental responsibility.

One significant trend is an increased focus on sustainability and waste reduction. As environmental concerns grow, construction companies will face greater pressure to minimize their ecological footprint. Material tracking will play a crucial role here, enabling precise inventory management to prevent over-ordering, identify opportunities for recycling or repurposing surplus materials, and track the embodied carbon of materials from source to site. This aligns with the broader industry move towards achieving Scope 3 carbon tracking and other ESG (Environmental, Social, and Governance) goals. This directly contributes to cost savings and waste reduction by reducing disposal fees, optimizing material usage, and enhancing a company’s green credentials.

Another emerging technology with profound implications is the role of blockchain for an immutable chain of custody. Blockchain can provide a secure, transparent, and unchangeable record of every material’s journey, from its origin to its final installation. This “digital passport” ensures authenticity, tracks ethical sourcing, and provides an auditable trail, which is particularly valuable for high-value or regulated materials.

We will also see deeper integration with BIM (Building Information Modeling) for 3D material tracking. As BIM models become more sophisticated, material tracking systems will seamlessly integrate to provide a real-time, three-dimensional view of where every component is located within the digital model. This not only aids in installation planning but also allows for precise visualization of material progress and potential clashes. Matrak, for example, already syncs with BIM models to provide 3D tracking, showing the direction of this trend. You can explore their BIM integration capabilities here.

Finally, predictive analytics for forecasting material needs and supply chain disruptions will become standard practice. By analyzing historical data, market trends, and real-time project progress, AI-powered systems will be able to more accurately forecast material requirements, anticipate potential supply chain bottlenecks, and suggest proactive mitigation strategies. This foresight will allow companies to optimize procurement, negotiate better deals, and ensure material availability, further contributing to project scheduling and timely completion.

These future trends underscore a move towards highly intelligent, interconnected, and sustainable material management systems that will redefine efficiency and responsibility in construction.

Frequently Asked Questions about Construction Material Tracking

How does material tracking software improve project scheduling?

Material tracking software significantly improves project scheduling by providing accurate, real-time data on material availability. This means project managers can instantly see if all necessary components are on-site and ready for use. By eliminating guesswork and preventing delays caused by missing components, our systems allow for more reliable scheduling. Crews are never left waiting for materials to arrive or be found, which directly contributes to timely project completion and helps avoid costly idle time. This proactive approach ensures that the project progresses smoothly according to plan.

What is the best way to track construction materials on a large-scale project?

For large-scale projects, a multi-layered and integrated approach is undoubtedly the best. This involves using unique identifiers like QR codes or RFID tags on individual materials and entire pallets, all managed through a central, cloud-based software platform. This digital backbone provides real-time inventory visibility across vast sites. Supplementing this with AI-powered mobile surveillance units is crucial. These units can monitor large laydown yards, automatically verify deliveries against purchase orders, and proactively prevent theft, providing a comprehensive overview of all assets and activities. This combination ensures both granular tracking and overarching security.

Can material tracking reduce waste on a construction site?

Absolutely. Material tracking is a powerful tool for waste reduction. By maintaining an accurate, real-time inventory, you gain precise control over what materials are on site. This prevents common causes of waste such as over-ordering, materials expiring or deteriorating due to prolonged storage, and items being lost or damaged. Our team has seen clients significantly cut down on waste by identifying surplus materials for use on other projects or facilitating their return to suppliers. This not only saves money on procurement and disposal costs but also strongly supports sustainability goals, making construction more environmentally responsible.

Conclusion

Mastering construction material tracking is no longer an option but a critical necessity for profitability, efficiency, and project success in today’s complex construction landscape. We’ve journeyed from understanding the significant challenges posed by traditional, inefficient methods to exploring the transformative potential of cutting-edge technologies and advanced AI solutions.

The path to optimized material management lies in a holistic strategy that seamlessly integrates technology, refined processes, and empowered people. From the foundational reliability of barcodes and QR codes to the automated precision of RFID and the real-time insights offered by mobile applications, each technological step builds towards greater control. However, the true leap forward comes with AI-powered solutions, enabling proactive security, automated data verification, and actionable intelligence that turns raw data into strategic advantage.

By embracing these tools and best practices—carefully planning inventory infrastructure, fostering strong supplier relationships, implementing rigorous on-site protocols, and diligently measuring success through KPIs—construction companies can mitigate risks, reduce waste, and significantly improve their bottom line. The future of construction material management promises even greater integration with BIM, a heightened focus on sustainability, and the predictive power of analytics, all contributing to smarter, faster, and more secure project delivery.

By investing in and intelligently deploying these advanced material tracking systems, we empower construction companies to build smarter, faster, and more securely, ensuring every project is delivered on time, within budget, and to the highest standards.